Constantly Variable Transmissions CVT have two significant sorts one does not utilize a belt to communicate power, like Toyota’s Hybrid Synergy Drive, which utilizes mechanical pinion wheels; one more kind of CVT utilizes belts interfacing two pulleys. The primary kind enjoys the benefit of genuinely mechanical hard associations, high proficiency and high limit can deal with enormous force, however one impediment is that the Toyota Hybrid Synergy Drive, its mechanical design must be utilized in half breed powertrains, that transmission would not work in a conventional inward ignition motor controlled vehicle. For the belt type CVT, it tends to be utilized in all vehicles with various kinds of force sources, and it has limitless stuff proportions; however since it relies upon the grinding between the belt and the pulley to conveyance energy, its capacity to send force is restricted; and its proficiency under high burden is not comparable to other customary programmed transmissions.

As of late, VIT Automobile Science and Technology Ltd, an organization worked in transmission innovation, situated in Beijing, China, delivered some data about their most recent item moveable teeth CVT they called it HN-CVT. The following is one of its creation units. The HN-CVT joins the advantages of the over two referenced CVTs. As indicated by VIT, they as of now have one model of the HN-CVT with force rating additionally; the HN-CVT has a shocking high proficiency proportion of 96% it just loses 4% of the energy coming from the motor flywheel, prior to putting the capacity to the vehicle’s wheels. For examination, customary programmed transmissions normally have a proficiency proportion between 80% – 90%. The rule of the HN-CVT moveable teeth CVT depends on the essential of how a vehicle transmission functions.

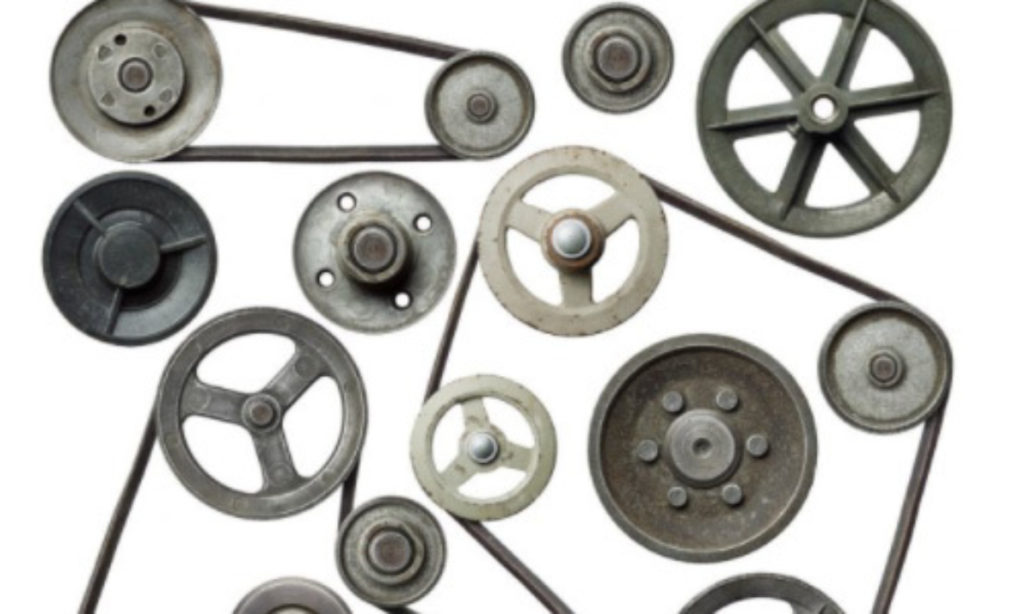

Notwithstanding what kind of a transmission is, they all work thusly the info side is matched to stuff with a specific measure of teeth, and the yield side is combined with one more measure of teeth. In the event that the tooth measure of the two cog wheels is unique poleas de transmisión the information side and the yield side will pivot at an alternate speed. For the HN-CVT, it actually has a belt. Be that as it may, not the same as other CVTs, the belt has fixed teeth on it. The HN-CVT additionally has a pulley, yet it is a unique pulley it has many little steel sheets stuffed on its surfaces. Those little sheets can go all over separately constrained by the transmission ECU. In the event that a few sheets go up simultaneously, the raised shape it framed becomes one tooth. For all the steel sheets on the pulley, the transmission ECU can handle their activity to frame various arched shapes, in this way it basically turns into stuff.